Automatic Continuous Planetary Ball Mill GX Series

Description:

Category:

SEND A MESSAGE:mt15@mitr.cn Inquire Now

一、Product Description

The GX Series Automated Continuous Planetary Mill is a groundbreaking, first-of-its-kind automated planetary milling system from MITR, integrating drying, preheating, precision grinding, and automatic particle size grading and discharge. It represents a significant innovation in sample pretreatment technology for both laboratory and small- and medium-volume industrial production. The independently controllable rotational and orbital speeds of the mill completely transform the traditional planetary milling process, which requires manual intervention for material loading, process monitoring, and product collection. Instead, it delivers a complete closed-loop automated process: "raw material feeding → precise drying and temperature control → automatic ball mill loading → efficient planetary grinding → intelligent coarse and fine material grading and collection."

The GX Series' core design philosophy is to achieve high efficiency, improved consistency, and fully automated operation. By integrating a precise positioning and conveying system, an intelligent control system, and an optimized grinding jar design, the system automatically controls material drying and temperature, precisely metering and evenly loading the jar, and setting and executing complex grinding programs (including drying temperature control, speed, time, and forward and reverse cycles). After grinding, the ground material is automatically transferred to the grading bin, and the finished product is automatically discharged into coarse and fine grading bins.

| Application Areas

It is suitable for automated intelligent equipment in laboratory material research departments and production fields such as new energy, metallurgy, electronics, ceramics, geology, mining, building materials, chemicals, light industry, beauty, environmental protection, and matcha.

| Working principle

A planetary mill features four grinding platforms on a single turntable (see the image below). The grinding jar is eccentrically mounted on the sun gear of a planetary ball mill. The sun gear rotates in the opposite direction of the grinding jar, with a ratio of 1:2. This results in a superimposed rotational motion of the grinding balls in the jar, known as the Coriolis force.

The speed difference between the grinding balls and the grinding jar creates an interplay between friction and impact forces, releasing high dynamic energy. This interplay of forces enables planetary ball mills to achieve high and very efficient material size reduction.

The two parameters of revolution and rotation allow for convenient adjustment of compression force and crushing speed to accommodate powders of varying hardness and adjust production capacity. There are five main ways in which material moves within the grinding drum of a planetary ball mill:

1. Pulsation. The material moves away from the center of revolution as a group. After the jar rotates to a certain angle, it slides in the opposite direction of rotation. The grinding balls push the powder layer against the jar wall, exerting compression, shear, and friction on the material.

2. Dropping. After the jar rotates to a certain angle, the material, when the pressure on the jar wall reaches zero, is thrown away from the jar wall, exerting an impact on the material.

3. Circulation. The material rises along a concentric circular trajectory and then falls layer by layer, forming a circular flow, exerting compression, grinding, and friction on the powder.

4. The material moves in a circular motion with the grinding balls, sliding against them, exerting friction on the powder.

5. Adherence. The material adheres to the jar wall, rotating without sliding, and loses its pulverizing effect. However, it protects the jar wall and reduces wear. The circulation and sliding motions are primarily responsible for ultrafine grinding.

二、Features

| Full process automation control: from feeding, material drying, ball mill loading, grinding, material collection, grading and discharging, it can be completed automatically with one click.

| The drying and preheating chamber is integrated, which can be timed and kept at a constant temperature; the temperature can be adjusted from room temperature to 300℃.

| Adaptive jar positioning, intelligent positioning of the material rack rotating platform to take the material and inject it into the corresponding grinding jar.

| High uniformity filling system, four jars precise feeding, eliminating batch differences.

| Optimize grinding energy based on the characteristics of the material after drying, and easily achieve ultra-fine grinding capabilities.

| Intelligent particle size classification and discharging: Utilizing the integrated airflow classification system, the ground powder is automatically conveyed to the classification barrel and then discharged separately through the coarse and fine material ports.

| Equipped with a loader, the machine can automatically and repeatedly feed, grind and discharge materials, thus realizing small-batch production and meeting the needs of long-term, high-intensity grinding (additional function - loader).

| Variable speed from 10 to 800 rpm, 1:2 ratio.

| The gears use an oil pump for circulation lubrication, heat dissipation and cleaning of meshing debris.

| It can store 3 modes and 15 programs, and has power-off protection memory and self-start function.

| Process recipe data storage: supports multiple sets of parameter presets and one-click call of different material processing programs.

| Equipped with the emitr remote control system, it can be connected with computers, mobile phones, PADs and other terminals for intelligent control.

| Heating and grinding are automatically cut off when the door is opened, and the emergency stop switch is interlocked to ensure safe operation.

三、Technical Parameters

|

Applications |

Crushing, mixing, homogenizing, colloid grinding, mechanical alloying, mechanochemistry |

|

Application Areas |

New Energy, Geology/Metallurgy, Glass/Ceramics, Engineering/Electronics, Building Materials, Environment/Recycling, Agriculture, Chemistry, Biology |

|

Sample Characteristics |

Soft, Hard, Brittle, Fibrous |

|

Grinding Principle |

Impact force, friction |

|

Maximum Sample Size |

< 3 mm |

|

Final Output Particle Size* |

Used for colloid grinding, the sample is less than 0.1 micron |

|

Number of Grinding Platforms |

4 |

|

Grinding Jar Material |

Stainless steel, carbide, zirconium oxide, aluminum oxide, silicon carbide, silicon nitride, polyurethane, nylon, polytetrafluoroethylene, agate |

|

Speed Ratio Setting |

1:2 |

|

Operation Modes |

3 types: unidirectional, alternating forward and reverse, multi-stage |

|

Storable Programs |

15 |

|

Timer Setting |

emitr remote control system digital setting, run/stop time: 0-9999 minutes |

|

Power Failure Protection |

Power-off protection memory self-start function |

|

Model |

GXQM-4L |

|

Grinding Jar Capacity* |

50-1000ml |

|

Revolution speed |

5-400r/min |

|

Rotation speed |

10-800r/min |

|

Power |

1.1KW(Grinding host) |

|

Voltage |

AC220v, 50/60Hz |

|

Dimensions (W x H x D) |

1470*1080*1200mm |

|

Weight |

About 750kg (Grinding host) |

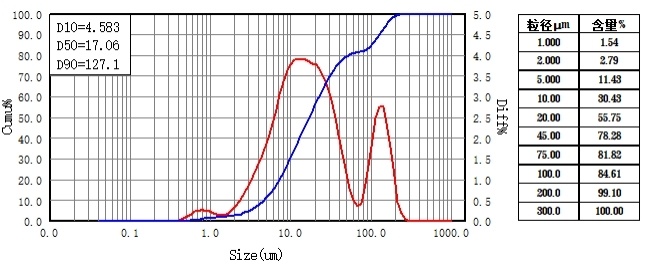

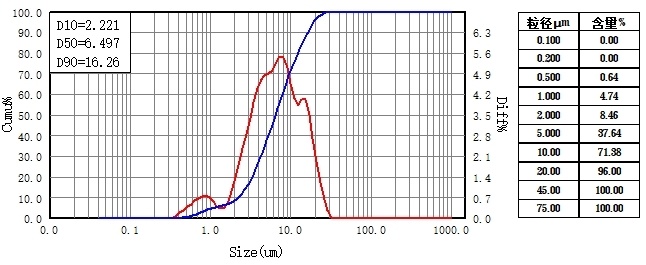

四、Grading particle size detection (experimental case)

| Grinding material: activated carbon powder

| Grinding plan: duration 20 minutes (forward rotation 10 minutes, rest 5 minutes, reverse rotation 10 minutes, rest 5 minutes); grinding speed 400 rpm.

| Particle size test results:

coarse material d50=17μm,d90=127μm

coarse material d50=5μm,d90=16μm

Previous

Previous

MESSAGES