Omnidirectional Planetary Ball Mill QM series

Description:

The QM series of full-directional planetary ball mill are patented products of the third generation of planetary ball mills (patent number: ZL 2016 2 0089490. 1). The difference from the vertical planetary ball mill is that when the mill jar is working, the planetary main plate can rotate 360° or work at any angle, so that the sample materials in the jar can fully participate in the grinding and mixing, thereby reducing the phenomenon of sample materials sinking to the bottom. It is suitable for wet and dry crushing and refining of hard, medium hardness, brittle and fibrous materials, and the sample fineness can be less than 0.1μm (colloid). It can also be used for grinding solids in suspensions, sample mixing and homogenization, and metal alloying, etc., and can achieve better results. The products are widely used in laboratory material research departments such as geology, mining, metallurgy, electronics, building materials, ceramics, chemicals, light industry, beauty, environmental protection, matcha, etc.

Category:

SEND A MESSAGE:mt15@mitr.cn Inquire Now

The extremely high centrifugal force of the omnidirectional planetary ball mill results in very high comminution energy, so the grinding time is short and the 360° rotation makes the discharge more uniform.

Suitable for all industries where the quality control process places the highest demands on purity, speed, fineness and reproducibility.

| Lossless size reduction to sub-micron range

| Wet grinding produces particle sizes in the nanometer range (<100 nm)

| Variable speed from 10 to 800 rpm, speed ratio 1:2

| Directly connected motor transmission provides stronger power, simpler maintenance, and longer service life

| Batch processing, up to 4 x 30/3500 ml samples, 4 samples can be processed simultaneously

| 360 ° rotation effectively reduces sinking phenomenon and grinds materials more evenly

| Can store 3 modes and 15 plans

| Power-off protection memory self-start function

| Can be used for dry grinding, wet grinding, vacuum grinding, and atmosphere-protected grinding

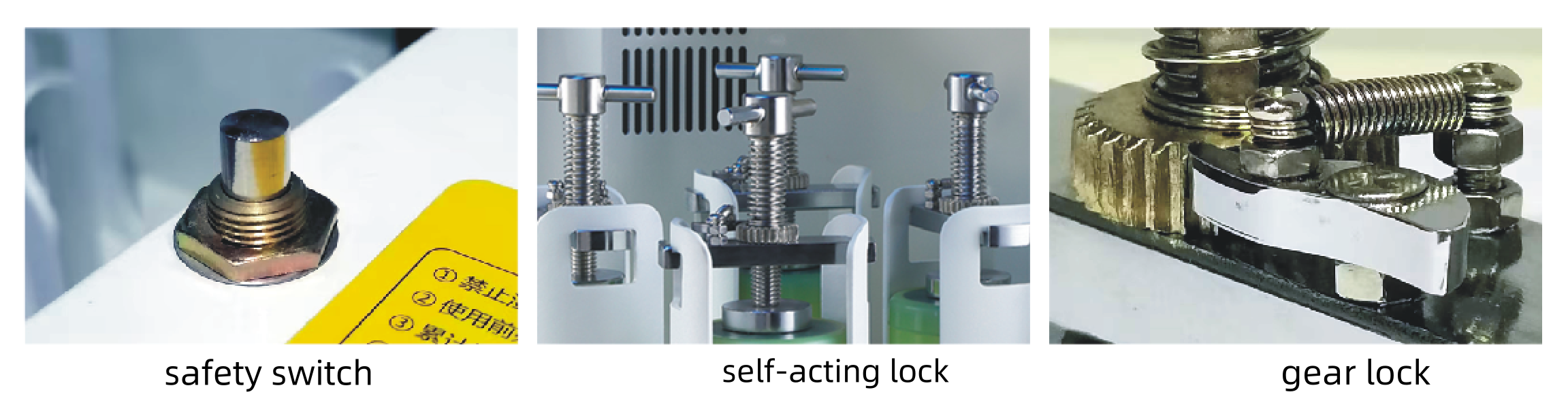

| The machine stops when the lid is opened, and the self-acting lock prevents loosening, ensuring safety.

| Equipped with rollers and swivel feet, it is easy to use the rollers when transporting and moving, and the swivel foot bracket will not move during operation.

The machine stops when the lid is opened, and the self-acting lock to prevent loosening

The QM series of planetary ball mills are safe to operate. They are equipped with a safety switch device. The machine will stop when the cover is opened and the equipment cannot start running when the cover is opened. This ensures the safety of the operator and prevents accidental injuries.

The self-acting lock can prevent the tank from loosening during operation, ensure safety and avoid damage to the core components of the equipment.

Wet grinding is used to obtain particle sizes below 5 µm, as small particles tend to get charged on their surfaces and agglomerate, which makes further grinding in dry mode difficult. By adding a liquid or dispersant the particles can be kept separated.

To produce very fine particles of 100 nm or less (nano-scale grinding) by wet grinding, friction rather than impact is required. This is achieved by using a large number of small grinding balls which have a large surface and many friction points. The ideal filling level of the jar should consist of 60 % small grinding balls.

Innovative & Outstanding Grinding Jar

The jar is made of refined molds or high-precision polishing, with extremely high smoothness of the inner and outer walls, and the bottom adopts a large R angle design that is more difficult to make, which can effectively reduce the phenomenon of materials sinking to the bottom during the grinding process.

The jar opening adopts a more ergonomic grip step to prevent hands from slipping and make it easier to take/put down the grinding jar.

QM Series Detail Processing

Typical sample materials

Planetary ball mills are ideal for metal oxides, alloys, carbon fiber, ceramics, charcoal, chemical products, clay minerals, coal, coke, compost, concrete, electronic scrap, fibers, glass, gypsum, hair, catalysts, cellulose, cement clinker, bentonite, bones, hydroxyapatite, iron ore, kaolin, limestone, minerals, ores, paints and varnishes, paper, pigments, plant materials, polymers, quartz, seeds, semi-precious stones, sewage sludge, slag, soil, tissue, tobacco, waste samples, wood, etc.

Technical Parameters

|

Applications |

Crushing, mixing, homogenizing, colloid grinding, mechanical alloying, mechanochemistry |

||||

|

Field of application |

New energy, geology/metallurgy, glass/ceramics, engineering/electronics, building materials, environment/recycling, agriculture, chemistry, medicine, biology |

||||

|

Feed material |

Soft, hard, brittle, fibrous—dry or wet |

||||

|

Size reduction principle |

Impact force, friction |

||||

|

Material Feed Size |

< 5 mm soil<10 mm |

||||

|

Final Fineness * |

Used for colloid grinding, the sample is less than 0.1 micron |

||||

|

No. of Grinding Stations |

4 |

||||

|

Grinding method |

Can be dry grinding, wet grinding, vacuum grinding, atmosphere protection grinding |

||||

|

Grinding jar material |

Stainless steel, carbide, zirconium oxide, aluminum oxide, silicon carbide, silicon nitride, polyurethane, nylon, polytetrafluoroethylene, agate |

||||

|

Speed ratio |

1 : 2 |

||||

|

Operation Mode |

3 types: unidirectional, alternating forward and reverse, multi-stage |

||||

|

Storable SOPs |

15 |

||||

|

Time setting |

Run/stop time: 0-9999 minutes |

||||

|

Power protection |

Power-off protection memory self-start function |

||||

|

Model |

QM-QX2L | QM-QX4L | |||

|

Grinding jar capacity |

50-500ml | 50-1000ml | |||

|

Vacuum jar capacity |

50-250ml | 50-500ml | |||

|

Revolution speed |

5-400r/min | 5-400r/min | |||

|

Rotation speed |

10-800r/min | 10-800r/min | |||

|

Power |

0.75kw | 0.75kw | |||

|

Voltage |

Single phase, 220V/50Hz | ||||

|

Dimension(W x H x D) |

850x890x960mm | ||||

|

Weight |

210kg | 215kg | |||

|

Model |

QM-QX8L |

QM-QX12L |

QM-QX16L |

QM-QX20L |

|

|

Grinding jar capacity |

500-2000ml |

1000-3000ml |

1000-4000ml |

1000-5000ml |

|

|

Vacuum jar capacity |

500-2000ml |

1000-3000ml |

1000-4000ml |

1000-5000ml |

|

|

Revolution speed |

5-320r/min |

5-320r/min |

5-230r/min |

5-230r/min |

|

|

Rotation speed |

10-640r/min |

10-640r/min |

10-460r/min |

10-460r/min |

|

|

Power |

1.5KW |

1.5KW |

3.7KW |

3.7KW |

|

|

Voltage |

Three-phase, 380V/50Hz |

||||

|

Dimension(W x H x D) |

1010 x 1050x 1230 mm |

1270 x 1100 x 1420 mm |

|||

|

Weight |

415kg |

415kg |

590kg |

590kg |

|

|

*Affected by sample material properties and instrument configuration/settings |

|||||

Working Principle

The grinding jar is eccentrically located on the sun wheel of the planetary ball mill. The sun wheel moves in the opposite direction of the grinding jar in a ratio of 1:2, and the grinding balls in the grinding jar are subjected to a superimposed rotational motion, the so-called Coriolis force.

The speed difference between the balls and the grinding jars creates an interaction between friction and impact forces, which releases high dynamic energy. The interaction between these forces makes the material size reduction in planetary ball mills high and very efficient.

The planetary main plate can rotate 360° or any angle continuously at the same time, so that the sample materials in the jar can be fully involved in grinding and mixing, thereby reducing the phenomenon of sample materials sinking to the bottom.

MESSAGES